Nothing is arbitrary in the design of the Antares. Every ounce, every joint, and every system is carefully considered. By blending advanced technology with hands-on craftsmanship, we deliver a catamaran that is performance-driven, seaworthy, and beautiful.

Hull construction

Strength and safety start with the hull. Our vacuum-infused fiberglass layup, reinforced bulkheads, and mast load engineering ensure Antares hulls can handle extreme bluewater conditions.

Explore in more detail:

Vacuum infusion takes our build quality a step further — delivering a lighter, stronger hull with unmatched consistency and durability.

How the process works

In 2023, Antares introduced vacuum infusion to replace traditional vacuum bagging. This advanced process uses a sealed mold, where resin is drawn evenly through layers of fiberglass and core material under carefully controlled vacuum pressure. As a result, every fiber is fully saturated, creating a consistent and void-free laminate.

Why it matters

This technique produces several important benefits:

-

Optimal strength-to-weight ratio — because less resin and more structural fiber are used, the hull becomes lighter and stiffer.

-

Superior consistency — each layer is fully saturated, eliminating weak spots and air pockets.

-

Eco-friendly efficiency — resin waste is reduced, creating a cleaner and safer work environment.

-

Long-term durability — stronger bonds deliver greater resistance to water intrusion.

✅ For owners, this means a catamaran that sails better, handles bluewater cruising well, and keeps its value for many years.

High-density foam cores and hand-laid fiberglass deliver unmatched strength, insulation, and safety in every Antares hull.

Our method

After the gelcoat surface is applied, Antares uses foam coring and precision fiberglass layup to build a hull that balances strength and performance. Each core panel is bonded under vacuum pressure. This guarantees 100% adhesion between the fiberglass layers and the core.

Advantages of our approach

-

Strength with weight savings — foam core stiffens the hull without unnecessary weight.

-

Thermal and acoustic insulation — as a result, life aboard stays quieter and more comfortable.

-

Vacuum bonding integrity — ensures a void-free bond between core and laminate.

-

Solid laminate below the waterline — this allows safer thru-hull fittings and easier repairs.

✅ These coring and layup techniques work together to create a hull that is strong and efficient. It is built to handle offshore conditions without any compromise.

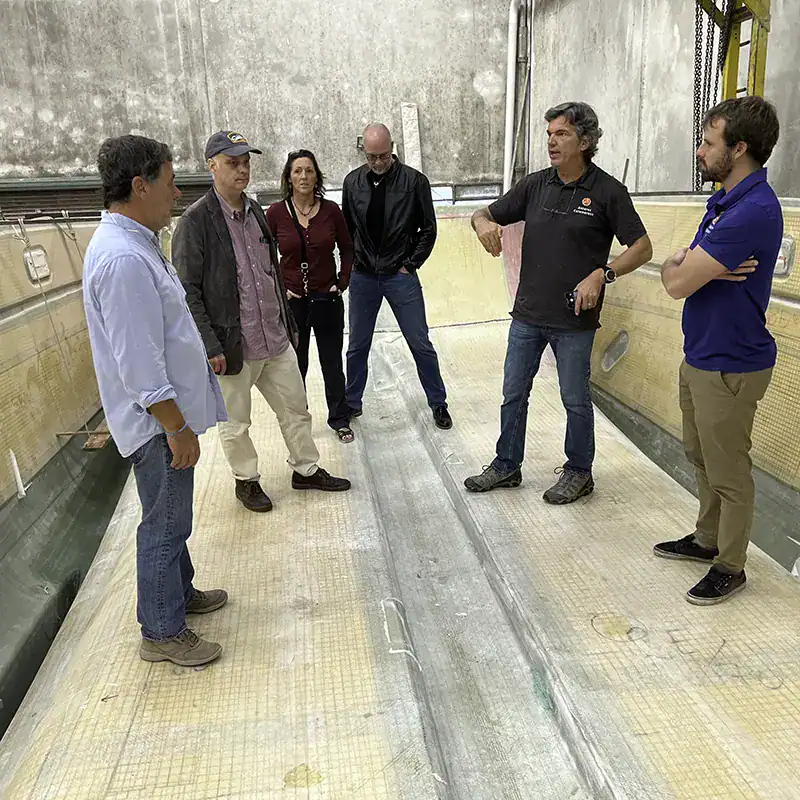

Precision hull assembly ensures the Antares 44’s structural integrity and uncompromising strength for bluewater passages.

Joining the hulls

Once the individual hull components are infused and cured, they are brought together in a carefully aligned assembly process. The outside port and starboard hulls are matched with the inner hull and bridgedeck mold. Once aligned, the sections are clamped, sealed, and reinforced with multiple layers of biaxial fiberglass. This process ensures the hull becomes a seamless, homogeneous structure.

Highlights

-

Seamless integration — structural joints are glassed over, which eliminates weak points.

-

Eight-layer reinforcement — biaxial fiberglass adds superior strength to the seams.

-

Durability-first design — each of the 36 molded pieces, from fridge doors to deck sections, is purpose-built to last.

✅ This meticulous assembly method guarantees that the Antares hull can withstand the rigors of offshore sailing with confidence.

Vacuum-infused structural bulkheads distribute mast loads, reinforce the hull, and add watertight integrity to the Antares catamarans.

Design and function

Bulkheads form the backbone of catamaran strength. On the Antares, three main bulkheads — mast, companionway, and steering — are designed to handle rigging loads. At the same time, they create watertight separations between living areas and storage spaces.

How they’re built

Using vacuum-assisted resin infusion, foam cores are layered with fiberglass and sealed under vacuum. Because of this, the result is a laminate that is stronger and free of voids.

Advantages

-

Superior strength-to-weight ratio — lighter yet stronger than traditional bulkheads.

-

Waterproof integrity — prevents water migration and de-lamination.

-

Load distribution — mast compression and rigging stresses are spread evenly across the bridgedeck and hull.

✅ Secondary bulkheads are added throughout the vessel. They help increase strength and improve efficiency in the building process.

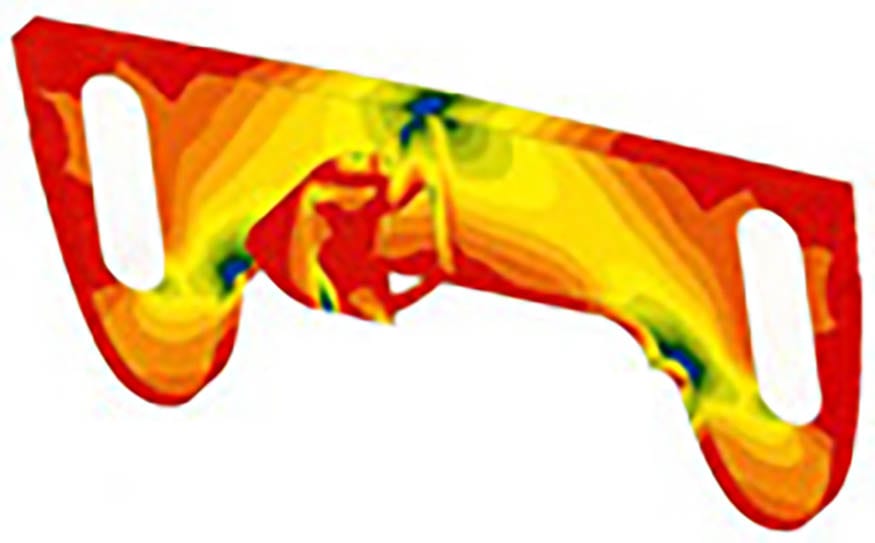

Engineered for offshore extremes, the Antares mast and bulkhead system is designed to withstand more than 3× the expected compression loads.

Load calculations

At 22,000 lbs displacement, the Antares 44’s mast is engineered to handle extreme forces. Finite element analysis (FEA) predicts mast compression loads at about 19,750 lbs. To ensure offshore safety, we design with a safety factor of 3 — meaning our mast and bulkheads can withstand up to 60,000 lbs of compression.

What this means for owners

-

Overbuilt safety margin — resilience against extreme offshore conditions.

-

Rigging optimization — catamarans experience 1.5× the loads of monohulls, and Antares is engineered accordingly.

-

Structural I-beam design — bulkheads, bridgedeck, and hull act together to spread mast loads efficiently.

✅ This engineering commitment means your Antares 44 can handle the demands of global passagemaking without compromise.

Hancrafted Interior Fit & Finish

The Antares 44 interior combines handcrafted cherry-veneer cabinetry with durable marine finishes — creating a warm, refined, and practical liveaboard home.

Explore in more detail:

Handcrafted cherry-veneer furniture brings warmth, durability, and timeless beauty to every Antares interior.

Craftsmanship inside

Once the major systems are installed, the interior finishing process begins — the stage where Antares craftsmanship is most visible. Each module, from the galley cabinetry to the saloon settee, is built on a workbench for precision. Later, these are glassed into the hull for added strength.

Key features

-

Cherry-veneer cabinetry — more than 65 cupboards and drawers, each adding storage and stiffness.

-

Vinyl headliner system — conceals wiring and insulation while improving acoustics.

-

Thermal & acoustic comfort — fabric and liner materials reduce noise and prevent condensation.

-

Durability-first details — modules are designed to resist movement and wear in a seaway.

-

Light & ventilation — windows and spacers are installed with precision to allow thermal expansion.

✅ For owners, this results in an interior that is beautiful to live in, structurally sound, and built to last the lifetime of the yacht — the essence of a true bluewater liveaboard.

Rudder and Steering System

The Antares has strong rudders, protective skegs, and a precise Jefa rack-and-pinion steering system. This design provides responsive control and reliability on every trip.

Explore in more detail:

Skeg-protected rudders and Jefa precision steering deliver unmatched safety and reliability offshore.

Rudder design

Our rudder system begins with custom fiberglass rudders built around a lightweight core and attached to a 316L stainless steel stock. Each stock is supported by three low-friction UHMW bearings. This design ensures smooth operation and long-term durability.

Skeg protection

A full skeg surrounds the rudder stock. Because of this, we can use a lighter stainless shaft without compromising strength. The skeg also absorbs impact loads and resists bending, which is critical for offshore voyaging.

Jefa steering upgrade

To complete the system, Antares installs the Jefa rack-and-pinion steering. This provides:

-

Direct, responsive feel at the helm in all conditions.

-

Low maintenance reliability for long service life.

-

Redundancy and safety for offshore passage loads.

-

Smooth operation with no play at the wheel, even under stress.

✅ The skeg-protected rudders and Jefa steering help Antares owners handle their boats easily. This setup reduces fatigue on long trips and boosts confidence in rough weather

Engine Placement

The Antares 44 has shaft-drive engines in the middle. This design gives it better balance and quieter operation. It also makes maintenance easier. All these features are made for bluewater cruising.

Explore in more detail:

Unlike saildrive catamarans, Antares uses shaft-drive power for long-term durability and offshore confidence.

Placement

On the Antares 44, the engines are placed amidships beneath the saloon floorboards instead of in the sterns. As a result, the center of gravity stays low and balanced, reducing pitching motion and improving performance under power.

Engineering features

-

Shaft-drive system — robust and reliable, avoiding vulnerable exposed parts.

-

Easy service access — fuel filters, strainers, and pumps are grouped for owner-friendly maintenance.

-

Noise and vibration reduction — acoustic insulation and flexible couplings create quieter passages.

-

Dripless shaft seals — carbon-graphite seals maintain perfect pressure.

✅ For owners, this means engines that are easier to service. They are also safer at sea and more comfortable to use. This is an important part of Antares’ bluewater design philosophy.

Replacing an engine on an Antares catamaran

Deck Construction & Installation

The Antares catamaran deck is built for strength, safety, and comfort — with a reinforced deck-to-hull joint and wide, unobstructed walkways.

Explore in more detail:

A reinforced deck-to-hull joint and 16-inch walkways give Antares owners confidence and safety on deck.

How it’s built

Every Antares deck is hand-finished, rotated, and inspected before bonding to the hull. The deck is first laid up upside down, then carefully rotated and fitted. Hatch openings and windows are trimmed for precision, and the fiberglass finish is inspected throughout.

Key design features

-

Structural deck-to-hull joint — the external flange is glassed with multi-directional fiberglass for strength and watertight integrity.

-

Toe-rail protection — protects against dock scrapes while strengthening the joint.

-

16-inch side decks — wide, unobstructed walkways ensure safe and easy movement.

-

Reinforced load areas — mast base, bulkheads, and rigging points are fully integrated.

-

Smooth interior finish — headliners conceal wiring, reduce noise, and create a refined look.

✅ For owners, this means a deck that is safe underfoot, strong under sail, and comfortable to live with — designed for the demands of full-time liveaboard cruising.

Time-lapse of a deck installed on an Antares hybrid

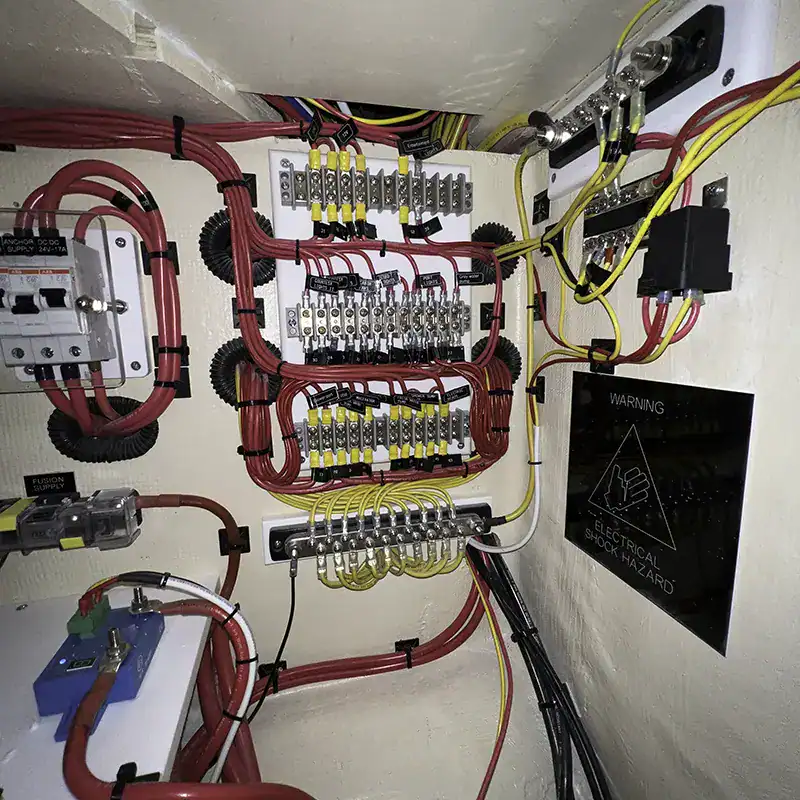

Electrical Systems

Behind the panels, Antares wiring is built to ABYC and CE standards, giving bluewater sailors the peace of mind that every connection is safe.

Explore in more detail:

Every Antares wire is color-coded, labeled, and documented — making troubleshooting simple, even offshore.

How it’s organized

From the start, Antares ensures every electrical connection is meticulously planned, built in-house, and documented. Harnesses are pre-fabricated, color-coded, and labeled to match reference drawings. As a result, troubleshooting and upgrades are simple, even offshore.

Key electrical features

-

Dedicated circuits — each major system is isolated on its own breaker.

-

ABYC & CE compliance — guarantees global safety standards.

-

Double-wall heat shrink — protects below-waterline connections from corrosion.

-

Chafe protection — wires are supported every 16 inches.

-

Immaculate panel layout — organized for clarity and confidence.

-

Owner documentation — numbered wires cross-reference to detailed diagrams.

✅ For owners, this means an electrical system that is safer, easier to maintain, and unmatched in reliability — a key advantage when cruising far from shore.